Test Coverage

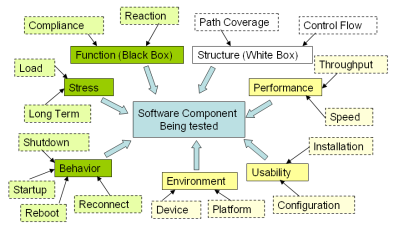

The certification test contains scenarios that simulate a real environment and real use cases for the test candidate. Therefore not only the pure function test of the OPC interfaces is done also a behavior, a load- and performance test and an environment- with 36h long-term test is accomplished. The expectation is that a certified OPC product has a significantly better quality and proves this through network interruption, start up behavior, usability and configuration. For example an HMI/SCADA Client should recognize an interrupted connection to an OPC server and should autonomously try to re-establish the link.

An OPC server should recognize when the connection to one of it's data source devices gets lost, indicate the faulty variables, but the communication to an other still connected device should remain stable and unaffected.

The laboratory provides a reference environment including commonly used OPC products of some OPC member companies.A predefined environment for interoperability tests is provided because companies donated software and hardware to the laboratory and provide configuration support. Currently products of the following vendors are available: ABB, Beckhoff, Cyberlogic, GE Fanuc Intelligent Platforms, Iconics, Kepware, Matrikon, OSIsoft, Rockwell Automation, Siemens, Softing, Software Toolbox and Wonderware.